With regard to structure and type of application, we can distinguish several basic types of industrial perpetual screws. Tray screw conveyors are equipped with a special enclosure the shape of which resembles letter U or V. Removable lids allow easy access to the perpetual screw, so this type of feeders is used at any place that involves the risk of transporting elements getting wedged or stuck. Devices are produced in several load versions: light, medium, and heavy. Upon request, they can be adjusted to the ATEX standard.

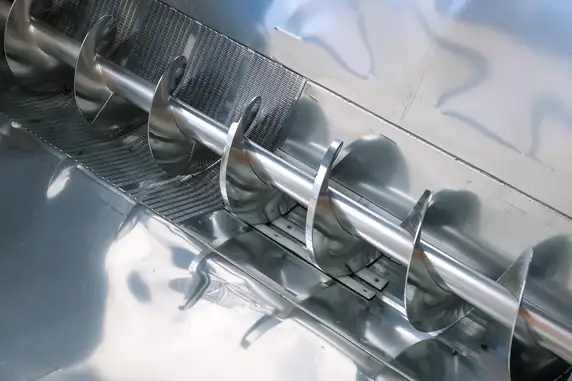

We own a CNC machine that allows forming blades through cold forming. As a result, we are able to provide a screw conveyor with blades that offer a wide range of parameters. We create elements that feature unique precision and repeatability. Devices meet the rigorous standards included in the currently applicable European directives, which is confirmed by the attached certificates. We provide screw conveyors made of stainless steel, heatresisting steel, or even acid resistant steel.

Transport with a screw is performed horizontally, at a specific angle, or vertically. The modular construction of those devices facilitates adjusting them to specific functions, i.a.: feeding, selecting, and dosing. We use powder coating to paint industrial perpetual screws with a selected RAL color.