When producing blades of HB400 steel, we are aware that such elements are to be adjusted to very difficult conditions. The blades we form with cold forming provide resistance to abrasion while maintaining the required quality and technological parameters. Parameters that are possible to be determined, such as hardness of metal sheet, make blades of wear-resistant steel have a repeatable life so that it is easy to schedule their maintenance and predict the wear. The application of HARDOX metal sheets causes the steel spiral become resistant even to extreme impacts and transport of materials with high ratio of external friction.

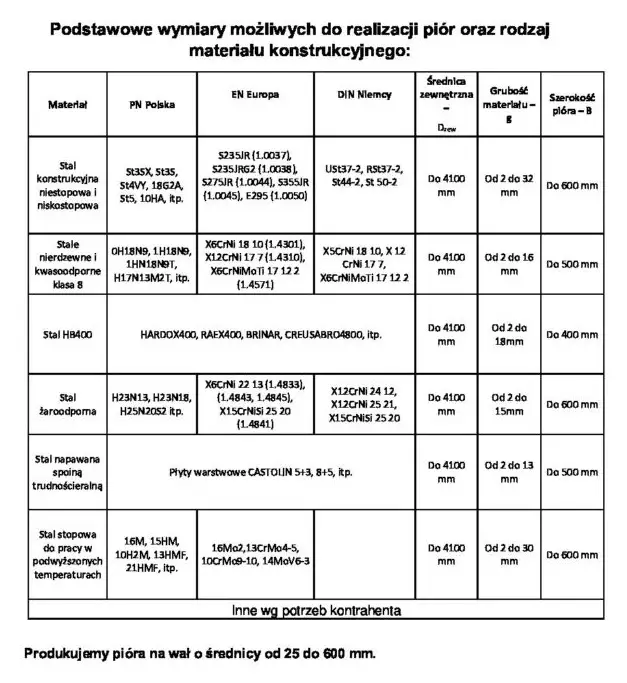

of construction steel – by using sheets with thickness of 2 to 32 mm at a maximum height of the blade ribbon of 600mm and cross-sectional area of the bent material of 192 cm2,

of stainless, acid resistant steel - by using sheets with thickness of 2 to 32 mm at a maximum height of the blade ribbon of 600mm and cross-sectional area of the bent material of 96cm2,

wear-resistant, heat-resistant, and specialpurpose steel - by using sheets with thickness of 2 to 32 mm at a maximum height of the blade ribbon of 600mm and cross-sectional area of the bent material of 192 cm2.

The shafts we produce have diameters from 25 to 600 mm, both round and square. Thanks to an advanced machinery park, we can offer mass production at maximum limitation of costs.